Services

Reliable Machining Services. Exactly.

We are a job shop and production facility in Omaha, Nebraska handling small and large runs of machined parts for your unique product or manufacturing!

Albert Precision Machining services include CNC Milling, CNC Lathing, and Surface Grinding. As a job shop and production facility, we handle both small and large runs of wide varieties of precision machined parts used for your product, assembly, or manufacturing. The techniques our machinists use to make precise parts include milling, lathing, grinding, broaching, turning, threading, angles, radiuses, tool and die, and more. Our skilled team can take care of the design and prototype of your machined part for you, or we can work with your existing designed drawing or print. We pride ourselves in getting parts exactly to your specifications down to the thousandths of an inch. We know that a small hairline makes a big difference in your end product. To request a quote, click here.

Our services reach locations far and wide as we serve customers throughout the Midwest and across the United States; from locations in Nebraska, Iowa, South Dakota, Missouri, and beyond. Learn more about us here.

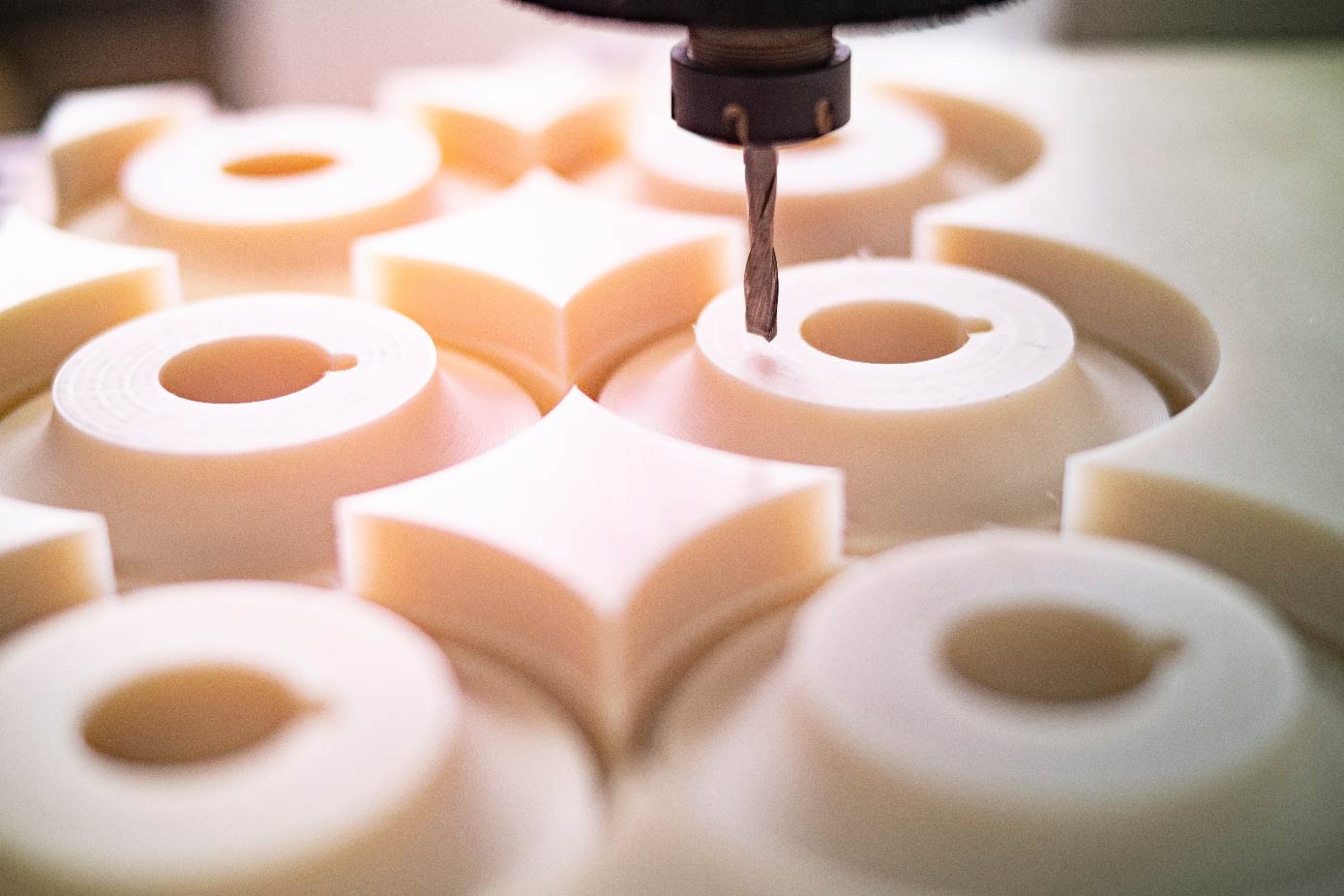

At our machining facility, we specialize in providing top-tier CNC milling services that seamlessly transform solid blocks of material into intricate, custom-designed parts tailored to meet your exact specifications. Whether you require simple, flat components or highly complex geometries with intricate detailing, our state-of-the-art CNC milling machines are equipped to handle the task with precision and efficiency.

Precision CNC Milling Services

Our CNC milling machines utilize high-speed spindles and advanced cutting tools to remove material with remarkable accuracy, ensuring that every contour, edge, and dimension aligns perfectly with your requirements. From prototyping to full-scale production runs, we offer consistent and repeatable precision that guarantees top-quality results for every project.

One of the standout benefits of CNC milling is its versatility. Whether you need components made from aluminum, stainless steel, titanium, plastics, or composite materials, our cutting-edge equipment and skilled machinists ensure that the finished product meets the highest industry standards. We work closely with you throughout the process, offering design recommendations and material insights to enhance manufacturability while maintaining structural integrity and cost efficiency.

Furthermore, our CNC milling capabilities include multi-axis machining, allowing us to create complex features such as undercuts, intricate pockets, and sharp contours that would be difficult or impossible to achieve with conventional machining methods. With our commitment to precision and quality, you can trust that every part we produce will function flawlessly in its intended application.

Advanced CNC Lathing for High-Precision Components

In addition to milling, our CNC lathing services are designed to shape raw materials into precisely crafted components with smooth finishes and exceptional accuracy. Our cutting-edge CNC lathe machinery allows us to create symmetrical parts with tight tolerances, making it the ideal solution for producing shafts, bushings, fittings, and other cylindrical or conical components.

CNC lathing works by rotating the workpiece against a stationary cutting tool, allowing us to remove material efficiently and achieve smooth, consistent shapes with minimal waste. Whether you require simple round parts or complex geometries with intricate detailing, our lathe machines are equipped to deliver outstanding results.

We specialize in both small-batch and large-scale production runs, ensuring that every component is fabricated with the same level of precision and attention to detail. Our CNC lathing services are engineered to provide the high-quality parts you need to keep your projects moving forward.

Our expertise also extends to secondary operations such as threading, drilling, and finishing, giving you a complete machining solution under one roof. With advanced programming and automated tooling, we can efficiently produce components that meet the most stringent quality standards while reducing lead times and minimizing production costs.

Surface Grinding for Impeccable Finishes

To achieve superior surface quality and precise dimensional control, our surface grinding services provide an essential finishing step for machined parts. Surface grinding is a highly effective process that uses a high-speed rotating abrasive wheel to remove material, ensuring a perfectly flat and smooth finish.

Whether you’re working with metals, plastics, or other materials, our skilled machinists utilize advanced grinding techniques to achieve surfaces with tight tolerances and impeccable consistency. This process is crucial for applications requiring enhanced wear resistance, improved aesthetic appeal, and seamless part integration.

Our surface grinding services are widely used in all industries where the quality of the finish plays a crucial role in overall component performance. By carefully controlling the grinding parameters, we can ensure that your parts meet the strictest dimensional and surface requirements, delivering components that exceed expectations in both form and function.

Materials We Use

At Albert Precision Machining, we work with a wide range of materials, ensuring that every machined part meets the highest standards of accuracy, durability, and functionality. Our highly technical and state-of-the-art machines are designed to accommodate countless materials, allowing us to craft components that align perfectly with your project’s unique requirements. We offer expertise in machining a wide variety of materials, including but not limited to:

Steel & Stainless Steel

Steel and stainless steel are among the most commonly used materials in machining due to their strength, durability, and resistance to wear and corrosion. Stainless steel, in particular, is ideal for applications requiring excellent resistance to rust, oxidation, and harsh environmental conditions.

Brass

Brass is a highly machinable material that offers excellent electrical conductivity, corrosion resistance, and an attractive appearance. It is often used for precision components in the electrical, plumbing, and decorative industries. Due to its low friction properties, brass is also ideal for gears, valves, and fittings.

Aluminum

Lightweight yet strong, aluminum is an ideal material for applications where weight reduction is a priority without compromising strength. It has excellent thermal conductivity, corrosion resistance, and ease of machining. Aluminum is also a preferred material for prototypes and high-speed machining applications.

Plastic

Plastics offer a unique combination of lightweight properties, corrosion resistance, and flexibility. We machine a variety of different engineering plastics. These materials are non-conductive and chemical resistant.

Specialty Metals

For applications requiring enhanced properties, we offer precision machining of specialty metals such as titanium, copper, and other high-performance alloys. These materials are commonly used in high-stress environments where strength, heat resistance, and longevity are critical.

And More!

If you have a specific material requirement not listed above, don’t hesitate to reach out. Our team is continuously expanding our machining capabilities and material expertise to accommodate even the most specialized project needs.

Industries We Serve

Precision Machining Services for a Wide Range of Industries

At Albert Precision Machining, we specialize in crafting high-quality machined parts tailored to the needs of a diverse range of industries. Whether you’re in food production, agriculture, construction, manufacturing, or industrial equipment, we have the expertise and technology to deliver precision-engineered components that meet your industry’s unique specifications. Our advanced machining capabilities ensure that every part we produce adheres to the highest standards of durability and accuracy.

We understand that different industries have different requirements when it comes to materials, tolerances, finishes, and regulations. That’s why we work closely with our customers to ensure that every component we manufacture is optimized for its intended use. From small, intricate parts to large-scale production runs, our team is committed to delivering superior results that enhance the efficiency and reliability of your operations.

At Albert Precision Machining, we take pride in serving a wide array of industries, offering precision-machined components that power essential applications across multiple sectors. Our machining expertise extends to, but is not limited to, the following industries:

Agriculture

The agricultural industry relies on durable, high-performance parts to ensure the efficiency and longevity of farming equipment. We manufacture precision components for tractors, irrigation systems, harvesting equipment, and more. Our parts are designed to withstand extreme weather conditions, heavy usage, and demanding environments.

Construction

The construction industry requires tough, long-lasting parts that can endure heavy loads and continuous operation. We produce custom-machined components for construction vehicles, hydraulic systems, cranes, and structural equipment. Whether it’s a high-strength steel part or a corrosion-resistant component, our machining solutions contribute to the reliability of the construction sector.

Food Processing & Packaging

Precision is critical in food processing and packaging machinery. Our machining processes ensure that components meet strict requirements while maintaining durability and efficiency. We work with stainless steel and other food-safe materials to create machine parts that help streamline production in the food industry.

Industrial Equipment & Machinery

From manufacturing plants to heavy machinery, we produce high-precision parts that keep industrial equipment running smoothly. Whether it’s custom shafts, housings, gears, or brackets, our machining solutions enhance the performance of critical machinery used in factories and processing plants.

Manufacturing

The manufacturing industry depends on precision-machined parts to support automated systems, robotics, and custom machinery. We provide components that help optimize production efficiency, reduce downtime, and improve overall equipment functionality. Our capabilities allow us to produce parts for a wide range of manufacturing applications.

Utilities & Energy

Energy and utility companies require high-performance parts for power generation, water treatment, and infrastructure maintenance. We supply precision components that meet the stringent demands of the utilities sector, ensuring safety, reliability, and long-term operational efficiency.

And More!

If your industry isn’t listed here, don’t worry—we have the expertise and flexibility to accommodate custom machining requests for many other sectors. Our team is always ready to take on new challenges and develop tailored machining solutions to meet your needs.

Why Choose Us?

Precision Machining Services and Unique Machined Parts Done Exactly.

- Advanced Technology & Precision Equipment – Our facility is equipped with state-of-the-art CNC machines, allowing us to produce high-quality components with exceptional accuracy.

- Versatility Across Materials – From metals like aluminum, steel, and titanium to engineering plastics and composites, we have the expertise to work with a wide range of materials.

- Comprehensive Machining Solutions – Whether you need milling, lathing, or grinding, we offer complete machining services to meet your manufacturing needs.

- Skilled Machinists & Engineers – Our experienced team ensures every component is crafted with precision, efficiency, and meticulous attention to detail.

- Commitment to Reliability & Efficiency – We ensure that every part we produce meets or exceeds your industry standards. We complete jobs efficiently and as a small business we are both attentive and reliable.

From prototyping to large-scale production, our machining services are tailored to meet your specific needs. Whether you require intricate CNC-milled parts, high-precision lathed components, or perfectly finished surfaces, our expert team is ready to bring your designs to life with unmatched precision, done exactly.

Request a quote today to learn more about how our machining solutions can support your next project!